Industrial blowers are used to increase the pressure of the fluid in industrial processes. In industry, this fluid is mostly air. They are used widely in many ventilation applications in different industries. For pressure increments of air, fans, blowers and compressors are mainly used. Industrial blowers are categorized in between fans and compressors in the case of pressure increment. Blowers produce more pressure as compared to fans, but not as much in comparison to compressors. According to Air Conditioning and Mechanical Contractors Association of Australia (AMCA) there is a certain compression ratio associated with fans, blowers and compressors. The table below describes this differentiation:

|

Equipment |

Specific Ratio | Pressure Rise |

| Fans | Up to 1.11 | 1136 |

| Blowers | 1.11 to 1.20 | 1136-2066 |

| Compressors | More than 1.20 |

As blowers increase the pressure of air, the pressure of effluent stream of air is multiplied as compared to influent stream. A complete blower system package includes rotor, driver, electric motor, pipes or ducts (from which air passes) and air conditioning equipment like a heat exchanger, air conditioner, refrigerator, filters and cooling coils etc.Industrial blowers are categorized in two major classifications

- Positive Displacement Blowers

- Centrifugal Blowers

These industrial blowers like the types that Custom Fans design, are categorized on the basis of their working mechanism. Positive displacement blowers intake a specific amount of fluid and throw air with the reciprocating action of an impeller of the working element. In centrifugal blowers, the impeller of the blower applies a centrifugal force on the fluid and thus increases the pressure of the fluid.

Centrifugal Blowers

Centrifugal blowers resemble centrifugal fans. An impeller inside the blower is a working element. It can rotate up to 15000 revolutions per minute. For greater pressures, multi stage centrifugal blowers are used, which are designed to be highly efficient. In multi stage blowers there are multiple impellers installed within the housing body so that air passes a number of impellers before it comes out. In single stage industrial blower, air doesn’t take as many turns so they are much more efficient.

Centrifugal industrial blowers can work against pressure ranges of .35 to .75 kg/cm2. As the pressure of the system increases, there can be enormous drop in air flow rate. That’s the drawback of industrial centrifugal blowers and why they are applicable when they are not prone to clogging.

In positive displacement industrial blowers, a fixed amount is entrapped and sent forward with greater pressure. They are great in the sense that they provide an even amount of air even if the pressure or flow rate varies. They are beneficial to application processes which are prone to clogging because they can produce pressures up to 1.25 kg/cm2. Positive displacement industrial blowers produce greater pressures as compared to centrifugal blowers. but their impeller or acting element rotates at lower rate i.e. 3600 revolutions per minute.

Industrial blower efficiency is the ratio between the power transferred to the air stream and the power delivered by the motor to the blower. Efficiency of the blower depends upon the type of impeller being used. As the flow rate of air increases, the efficiency of the blower will increase until a certain point, known as the peak or maximum efficiency. Blower efficiency can best be shown by the formula:

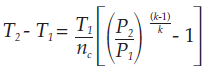

In this equation, nc represents blower efficiency, P2 is the effluent stream pressure and P1 is influent stream pressure, k is the ratio of specific heats and T1 and T2 represents temperatures of influent and effluent streams respectively.

The inner workings of an industrial blower are shown by the characteristic curves also known as efficiency or performance curves. It is a graphical representation of idealized as well as the real operation of blowers.

These equipments are a great way to increase the pressure of air. Now the industrial world is moving towards more efficient industrial blowers.