Industrial fan design varies according to need and industry. Industry machines sometimes require fans whose primary function is to provide a large flow of air or gas to various processes in different industries. This is achieved by rotating a number of blades, connected to a hub and shaft, and driven by a motor or turbine. The flow rates of these fans range from approximately 200 to 2,000,000 cubic feet (5.7 to 57000 cubic meters) per minute. A blower is another name for a fan that operates where the resistance to the flow is primarily on the downstream side of the fan.

Industrial fans have some special designs to match specific industrial purposes, but generally there are two type of fans: centrifugal fan and axial fan.

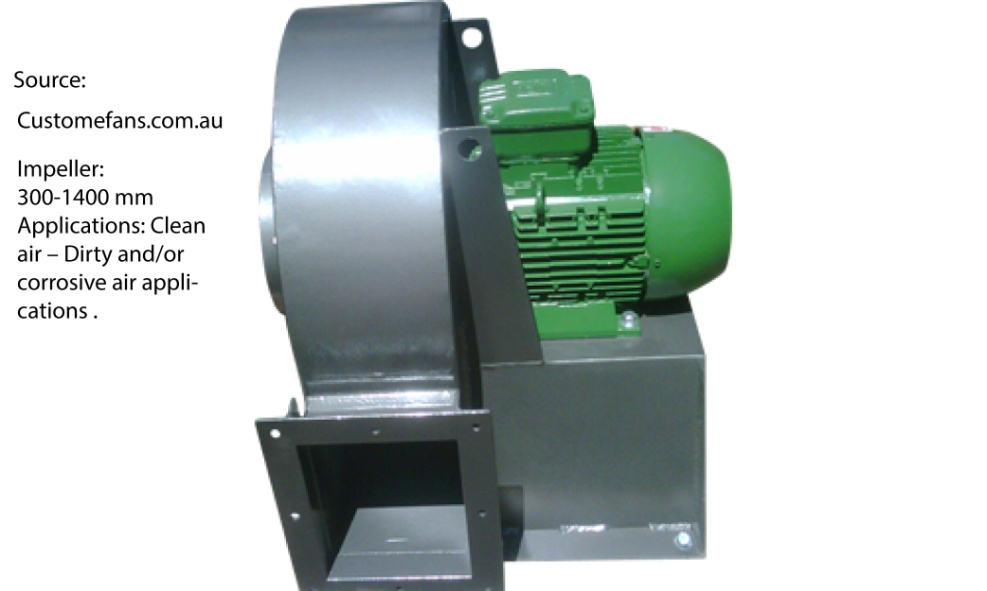

Centrifugal fan design

The centrifugal design uses the centrifugal force generated by a rotating disk, with blades mounted at right angles to the disk, they impart movement to the air or gas and increase its pressure. The assembly of the hub, disk and blades are known as the fan wheel, and often includes other components with aerodynamic or structural functions. The centrifugal fan wheel is typically contained within scroll-shaped fan housing, resembling the shell of the nautilus sea creature with a central hole. The air or gas inside the spinning fan is thrown off the outside of the wheel, to an outlet at the housing’s largest diameter. This simultaneously draws more air or gas into the wheel through the central hole [2]. Inlet and outlet ducting are often attached to the fan’s housing, to supply and/or exhaust the air or gas to the industry’s requirements.

Axial fan design

The axial design uses axial forces to achieve the movement of the air or gas, spinning a central hub with blades extending radially from its outer diameter. The fluid is moved parallel to the fan wheel’s shaft, or axis of rotation. The axial fan wheel is often contained within a short section of cylindrical ductwork, to which inlet and outlet ducting can be connected. Axial fan types have fan wheels with diameters that usually range from less than a foot (0.3 meters) to over 30 feet (9 m), although axial cooling tower fan wheels may exceed 82 feet (25 m) in diameter.

In general, axial fans are used where the principal requirement is for a large volume of flow, and the centrifugal design where both flow and higher pressures are required.

Industrial fans design

For industries where the application requirements do not vary greatly and applicable fan designs have diameters of around 4 feet (1.2 meters) or less, a standard or pre-engineered design might be selected. For Custom Fans, when the application involves more complex specifications or a larger fan, then a design based on an existing model configuration will often satisfy the requirements.

Many model configurations already cover the range of current industry processes. An appropriate model from the fan company’s catalogue is selected, and the company’s engineers apply design rules to calculate the dimensions and select options and material for the desired performance, strength and operating environment. Some applications require a dedicated, custom configuration for a fan design to satisfy all specifications.

All industrial fan designs must be accurately engineered to meet performance specifications while maintaining structural integrity. For each application, there are specific flow and pressure requirements. Depending on the application, the fan may be subject to high rotating speeds, an operating environment with corrosive chemicals or abrasive air streams, and extreme temperatures. Of the industrial fan designs larger and higher speeds produce greater forces on the rotating structures; for safety and reliability, the design must eliminate excessive stresses and excitable resonant frequencies.